“... HPC users may have an market advantage in the future on the market” – interview with Dr. Márton Gróza and Dr. Dávid Felhős

Dr. Márton Gróza (2)

What is the main profile of the company, what do you do at Karman Meachanics?

Dr. Dávid Felhős: Basically speaking, we are an engineering firm and we are mechanical engineers. We conduct technical simulations for the industry, and we also have a small production unit in addition to that. We test the products of machinery and equipment manufacturers in the virtual world to whether they can withstand the stress they will be submitted to. This is our main profile: running computer simulations of components responding to those stresses, and we have to estimate their lifetime.

Dr. Márton Gróza: Engineering design is carried out using 3D simulations – this is our starting point. The main advantage of having simulations is that you can make modifications in the virtual space, and prototypes will only be produced of those that are highly likely to pass real-world tests too. In addition to strength, dynamics, and lifetime simulations, we also perform fluid mechanics simulations and rheology simulations.

How should one imagine this in daily life?

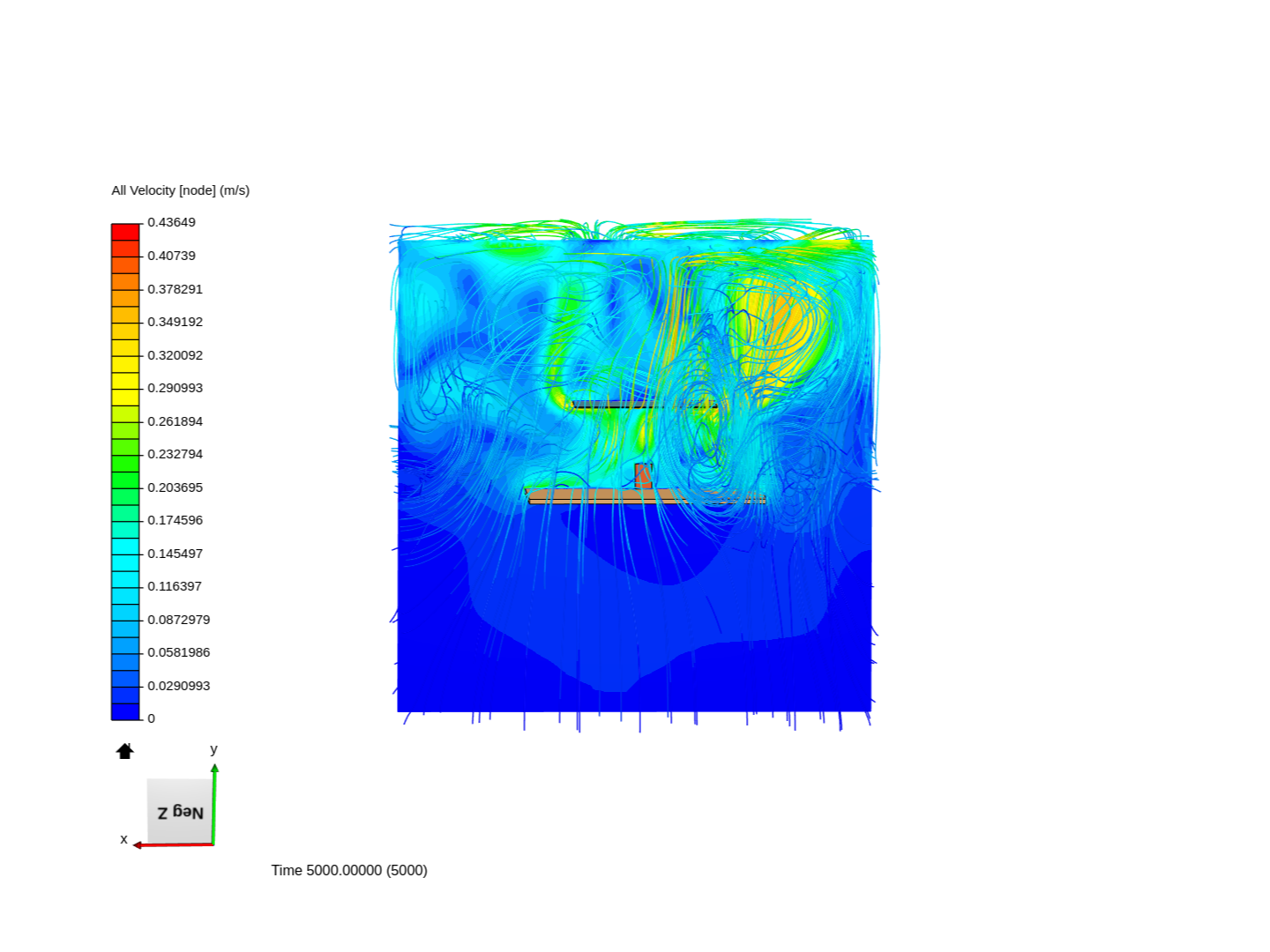

Dr. Dávid Felhős: For example, when designing electric equipment, one should expect such equipment to heat up and this should be taken into consideration already during the design phase. We enable our partners to do this.

Dr. Márton Gróza: In general, we join the engineering work of our partners in a late phase of development with our conventionally interpreted control calculations. However, it is becoming more frequent to see the virtual testing process supporting the work of constructors already from the beginning of the design process.

How much is it established practice to use simulations?

Dr. Márton Gróza: Mechanical engineering is an especially conservative field, and the application of the simulation experience in the development process is a practice that spreads slowly. There are experienced design engineers and technology experts who have a know-how that does not require simulations. Market experience confirms it in certain cases, but refutes it in other cases.

What role does supercomputing play in the operation of a company?

Dr. Dávid Felhős: Today, it is completely established and accepted to have the whole design process computerised. That is, design engineers prepare 3D models showing the connections and interactions between the components. Our calculations are prepared in the same way, in the virtual space. One advantage of doing so is that you can try the components without manufacturing them, and this means huge savings in terms of materials and working time. To largely simplify it: these 3D models prepared by the engineers are fed into a program, we put on the stresses, and the program calculates the load distribution among the components. This forms the basis for deciding whether it will withstand the physical strain.

What performance does a computer need for this?

Dr. Dávid Felhős: We need to do a vast number of things before completing these virtual statical and mechanical simulations, and of course, the calculations also need huge capacities. In order to render a specific component interpretable for the mechanical and physical equations known to us, we have to make it describable. This is achieved by subdividing the specific component into a finite number of units by projecting a so-called finite elementary network onto it. A complicated component is built up using small tetrahedrons and cubes, and the equations are applied to these tetrahedrons and cubes; these together will determine the behaviour of a specific component. The more tinier elements we can subdivide the tested component into, the better the calculation. However, the more elements we subdivide the test subject into, the more equations we have and the larger the associated CPU need. This is already cumbersome with desktop computers; you need enormous calculation capacities.

When did the two of you get to know supercomputing?

Dr. Dávid Felhős: From an industrial point of view, HPC that can be used with engineering software affordable to us started to crawl in a decade ago. In the beginning, nobody has any idea of what’s the use of this, and then they start to experiment with it and practice will tell.

Dr. Márton Gróza: Computer technology did not evolve by the gradual acceleration of a core as a result of the advances coming year by year. Instead, engineers started to install more cores into the machines, and of course, the performance of those also increases with time. We need to adapt to this, but it is not easy to split a mathematical task into a number of smaller tasks. It took and is still taking a lot of time to develop the solving algorithms capable of parallel execution and that's why the option of running them on HPC became industrial practice only about ten years ago.

For what purposes do you use supercomputers?

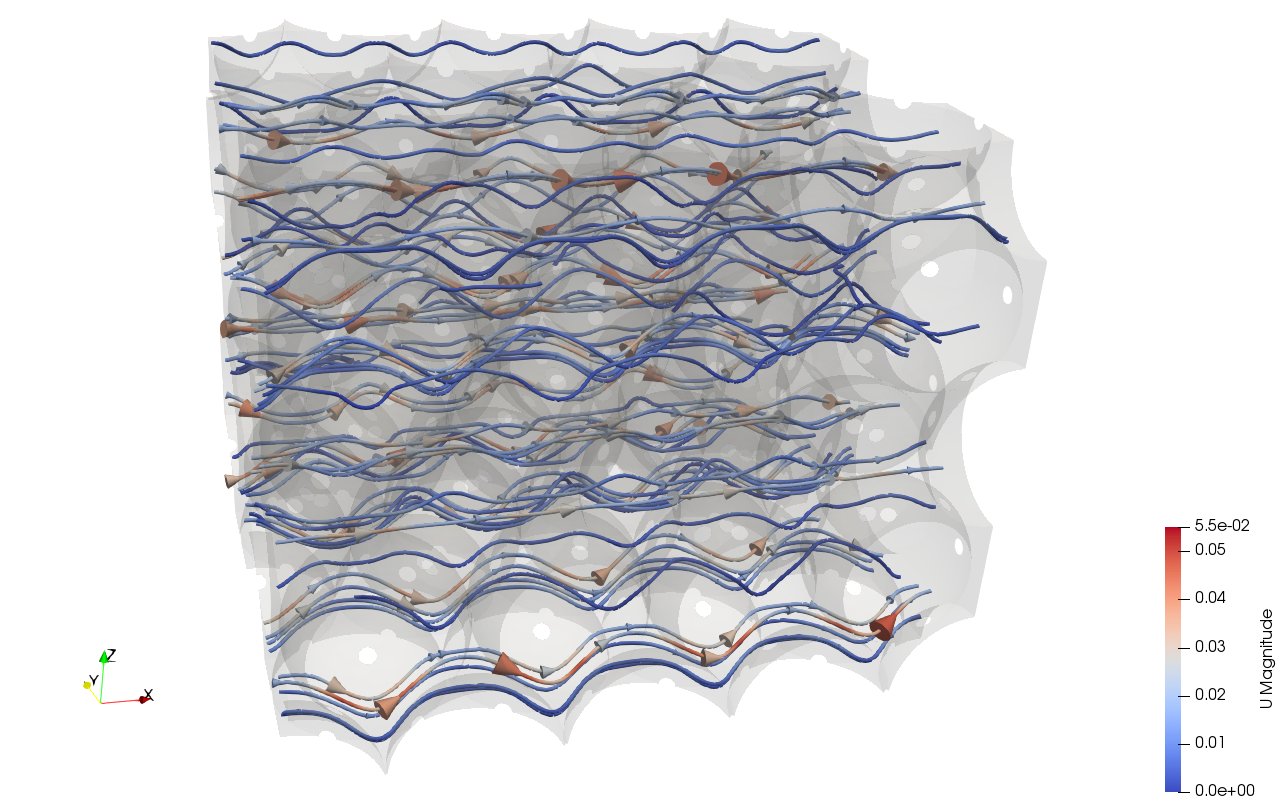

Dr. Dávid Felhős: Typically, these include rheology tasks, where you have to think of several million such small cubes. Each of them has more than one equation so we have to solve several million equations, and not only once but several times. Here, it does matter how many processors you have to do the calculation – the more you have, the quicker you get the results. These calculations may be running for a week, which is not even rare.

Dr. Márton Gróza: Our primary task is to convert engineering problems that arise into physical models. Next, it is the preparatory module of the software that does the conversion into a mathematical task with the help of an engineering expert in the field. This is already a set of linear equations, and that’s what the computer can solve. The efficiency of this is the merit of the solving algorithm – mechanical engineering work ends here. We can select and use good algorithms, but we do not develop solving algorithms. If we have a good algorithm, we look for resources that would efficiently cooperate with that – so that they do not significantly limit each other’s operation. Next, we interpret the results – evaluate them against the relevant standards, and translate the calculation results into a solution tof the mechanical engineering problem.

CFD simulation of the flow around an electronic component becoming heating up

Do your competitors also use supercomputers?

Dr. Márton Gróza: Companies pursuing cutting-edge industrial and mechanical development projects such as those in the vehicle industry and energy industry typically use HPC for running their simulations. The most common approach is to run commercial pieces of software on their own resources.

Dr. Dávid Felhős: Whoever conducts rheology simulations, will use HPC for sure – you’re out of the league without it. The very point of cooperating with KIFÜ is to open the door to as wide range of companies as possible where the use of HPC has a raison d’être. The goal is to make them use simulations and HPC, that is, they have to take two hurdles at the same time. However, licence fees for software with parallelisation capabilities are shockingly high because establishing such a software architecture requires enormous investments. The more processors you want to run your tasks on, the more licences you will need. Costs increase very quickly – almost no one can afford to run the calculations on 100 cores, at least when it comes to engineering firms and smaller companies.

So are parallel calculations a privilege of the big companies?

Dr. Dávid Felhős: Luckily, there are open source software applications with architecture prepared for HPC. These require much more from the users – but we are capable of creating environments that mitigate the associated engineering and professional challenge. And KIFÜ provides access to the infrastructure on which you can do that. There are two steps to reach at the same time: first, making simulations known and recognised by the industry and by companies that could use simulations but never thought about it because of the costs. The second one is HPC.

Dr. Márton Gróza: Open source software applications are primarily “by-products” of research activities, but researchers will not develop graphical user interfaces because that’s not what they focus on. However, despite having no user interface sometimes, such software may indeed represent alternatives to commercial software for certain applications. And then we are the ones to help find these applications and help users take the hurdle representing the application difficulties by providing training and auxiliary materials, advice, and consultancy.

What is the main challenge in this?

Dr. Dávid Felhős: To bring the software into a condition interpretable by engineers. That’s where we can contribute to the process.

What investments do you need for using HPC?

Dr. Márton Gróza: In addition to the purchase price or rental fees of the hardware, other considerations also emerge, on the mechanical engineering side too. As you increase the size of the problem to be fed into the HPC for a solution, the time and resources needed for the preparatory steps and for the evaluation will also increase proportionally. You will also need network connections of appropriate bandwidth because you have huge amounts of data.

Does the use of HPC improve the competitive potential of a company?

Dr. Márton Gróza: It is not even common practice in mechanical engineering to use simulation tools in all cases where they are recognisably required even in terms of cost-efficiency. Even less so is to characterise the operational behaviour of structures and pieces of equipment to a level of detail representing HPC needs. I think that the first step in increasing the competitive potential is to make the use of simulations common practice, and after a while, this will almost automatically be followed by the need to employ ever- increasing computing capacities, that is, HPC.

Dr. Dávid Felhős: First, you need to establish credibility, and then you can make them like HPC.

Dr. Márton Gróza: In many cases, limitations do not only include computing resources but also the other steps of the process. It is worth developing engineering simulation skills, the experience related to physical tests and the available HPC capacities in a proportional manner. With a simultaneous development of these, an improved competitive potential is almost inevitable.

What is the solution?

Dr. Márton Gróza: As regards industrial users, you only need to smooth the road and show the door, and they will find HPC with their problems.

Dr. Dávid Felhős: That’s right, the HPC playground needs to be made available, and it will work itself out.

What are the prerequisites of using HPC?

Dr. Dávid Felhős: You need to know a piece of software that is suitable for running on HPC.

Dr. Márton Gróza: Coming from a mechanical engineering background, one needs to be able to operate a piece of software that can make use of several cores on a user level – perhaps that’s how we can define the lowest level of the ‘entry' prerequisites.

Results of a CFD simulation of a gas passing through a porous medium

If you know one of them, will you manage the rest?

Dr. Márton Gróza: There is such an effect – the operation interfaces of 3D modelling systems and simulation tools do display certain similarities. However, if you change physical field, for example, from statics to rheology or electromagnetism, you will also need the theoretical background and the technical knowledge of the software.

Dr. Dávid Felhős: In the engineering world, knowing the software is not a goal. Software applications are always a tool. The goal is to solve a real industrial, physical problem. It is more efficient than making a prototype and then breaking it. We have to focus on what they can do with the software, and what fruits it will bring for them.

Do you have an HPC specialist at your company, or are such skills a basic requirement now?

Dr. Márton Gróza: All of our colleagues are able to compile simulations but HPC is only a tool for them.

Dr. Dávid Felhős: We do not aim to be HPC programmers. We act as integrators, and convert various competencies into useful outcomes.

What type of competitive advantages do you expect from KIFÜ’s supercomputer?

Dr. Dávid Felhős: We can achieve better results more quickly, but the really important thing is that we can use solutions which haven’t even been on the horizon. We are not only able to work with the simulations used before but also with a very complicated type of it for which we haven’t had the chance before. Fields have opened up where we can’t even predict the results one may achieve but will definitely generate profit.

Dr. Márton Gróza: For example, we can study the effects of more parameters within the same time period during a development optimisation project. As their experience dictates, engineers generally throw out most of the variables and will only use the software to evaluate 5 or 6 of them. That is, a lot of possibilities are discarded immediately. But when you have such large capacities, you don’t need to narrow down your tests – you can take other aspects into account, and you may try to simulate new things as well.

Have you ever had a project that would have been unfeasible without HPC?

Dr. Dávid Felhős: All of our rheology projects are like that.

Dr. Márton Gróza: Many physical problems can be studied by taking a steady-state as the baseline. For example, if you heat a house and both the heating output and the cold outside are constant, the walls will also have a constant temperature distribution after a while. This can be run relatively quickly. However, if you want to know how the house will cool down after the heating is switched off, then you have to have an almost real-time simulation, minute by minute. If for a day, then the simulation will also take at least a day. So-called transient simulations are slower than reality, so if you look at the whole house and it cooled down within a day, then it will take 3 to 4 days to have a realistic simulation.

Are there innovations in the field of the profile of your company that are a merit of HPC?

Dr. Márton Gróza: Innovation is a feature of the academic community.

Dr. Dávid Felhős: For us, engineers, innovation is quantum computers, fusion power plants or holograms.

Dr. Márton Gróza: If we interpret innovation as having its common, everyday meaning, then each of our simulations is used to test a new product, that is, we are part of an innovative activity. If a product does not change, we won’t test it – you don’t need to perform the same simulation twice. However, we participate in several development projects the experience of which will only be considered years later when manufacturing a new product – we have freer hands and we can test new ideas in such projects.

Is there any risk associated with HPC work? Can you exclude mistakes and errors?

Dr. Márton Gróza: Pain in the waist and back. Our models that have potential structural flaws may run faster and at higher costs, therefore, there may be a higher need for a more thorough review of the definition of the tasks.

Dr. Dávid Felhős: Not more than with a normal computer.

For what types of businesses do you recommend HPC?

Dr. Márton Gróza: It is important to have the professional background and skills in place so that someone can utilise the available capacities. Running your calculations on more cores alone will not “produce” better results. That is, for those whose previous experience in the field makes them feel that computing capacities are now the only limitation in finding solutions more quickly.

Dr. Dávid Felhős: For those who really know what they would like to do with it.

What was the most surprising thing about using HPC?

Dr. Márton Gróza: The earliest, bitter experience, which we got over relatively quickly, was that using two cores instead of one does not make the calculation twice as fast.

What do you think of the future of HPC?

Dr. Dávid Felhős: In the following 2 to 3 decades, HPC will undergo major unfolding. Methods that are completely different from the software applications we know now and more suitable for supercomputing will emerge. We will use HPC as we use a laptop today – we will perform much more complex simulations. Furthermore, simulations will emerge in fields that they do not even think of today – such as sociology. These will all have their economic driving forces, and we are only witnessing the first steps of it today; what’s more, quantum computers are also knocking on the door and they will open up new dimensions in all senses once they arrive.

Dr. Márton Gróza: The ball is now rolling in the field of algorithm development – we need to catch up with the opportunities offered by the hardware. Translating physical problems into mathematical models is a big challenge.

Dr. Dávid Felhős: Another challenge is education – to recognise that we have to go in this direction and we need skilled HPC users. Perhaps this is even a bigger a challenge than developing algorithms.